High Speed Corrugated Paperboard Automatic Flute Laminating Machine

Basic Info

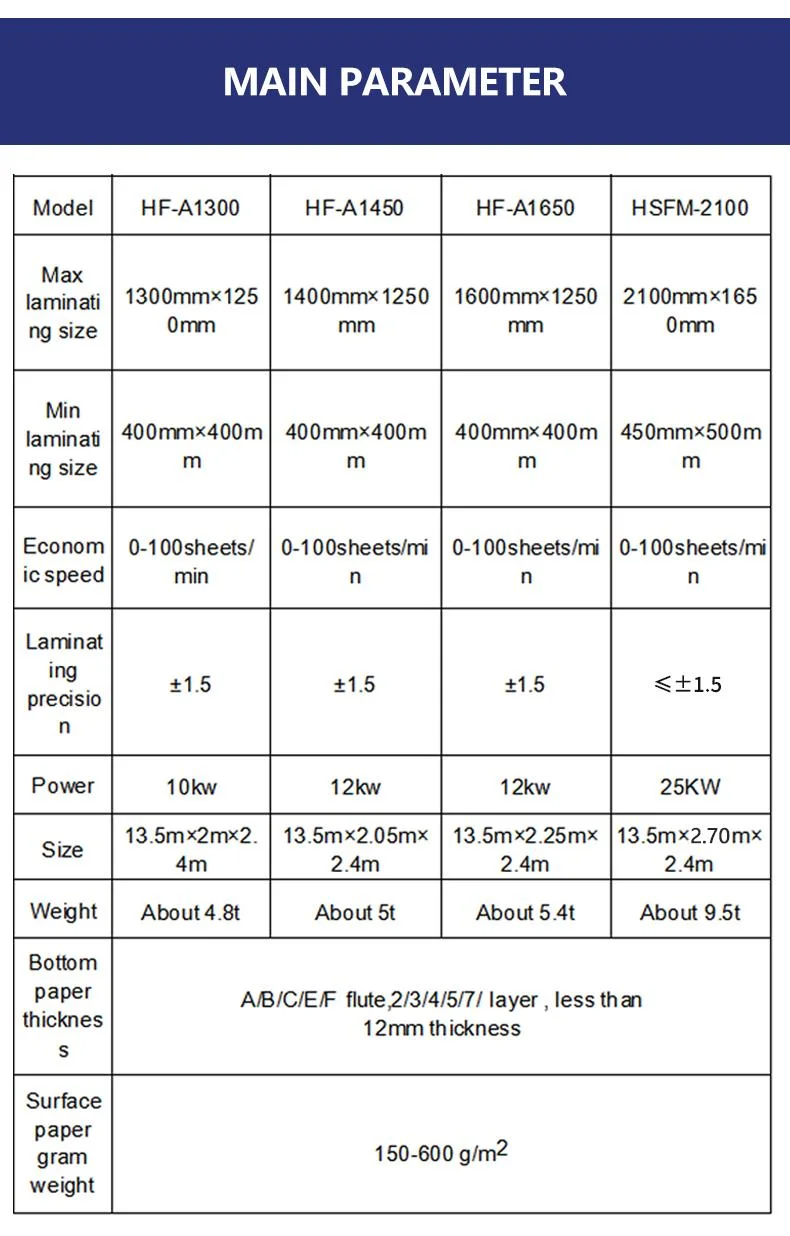

| Model NO. | HF-A1300 |

| Membrane Material | Paper |

| Plastic Film Mulching Modes | Cold Laminating |

| Performance | Anti Wrinkle |

| Maximum Size(mm) | 1300*1250 |

| Minimum Size(mm) | 400*400 |

| Top Feeding Paper Thickness | 150-600 G/M2 |

| Bottom Feeding Paper Thickness | a/B/C/E/F Flute,2/3/4/5/7/ Layer , Less Than 12mm |

| Laminate Precision (mm) | 1.5 |

| Max.Speed | 6000PCS/H |

| Overall Dimension | 13.5m*;2m*2.4m |

| Total Weight(T) | 4.8 |

| Total Power | 10kw |

| Transport Package | Plastic Film Wrapped+Wire Fixed in The Container |

| Specification | HF-A1300 |

| Trademark | Rino |

| Origin | China |

| HS Code | 844130 |

| Production Capacity | 10 Sets/Month |

Product Description

Corrugated Paper Board Automatic Flute Laminating Laminator Machine For Sale Product Description| Product description of flute laminating machine |

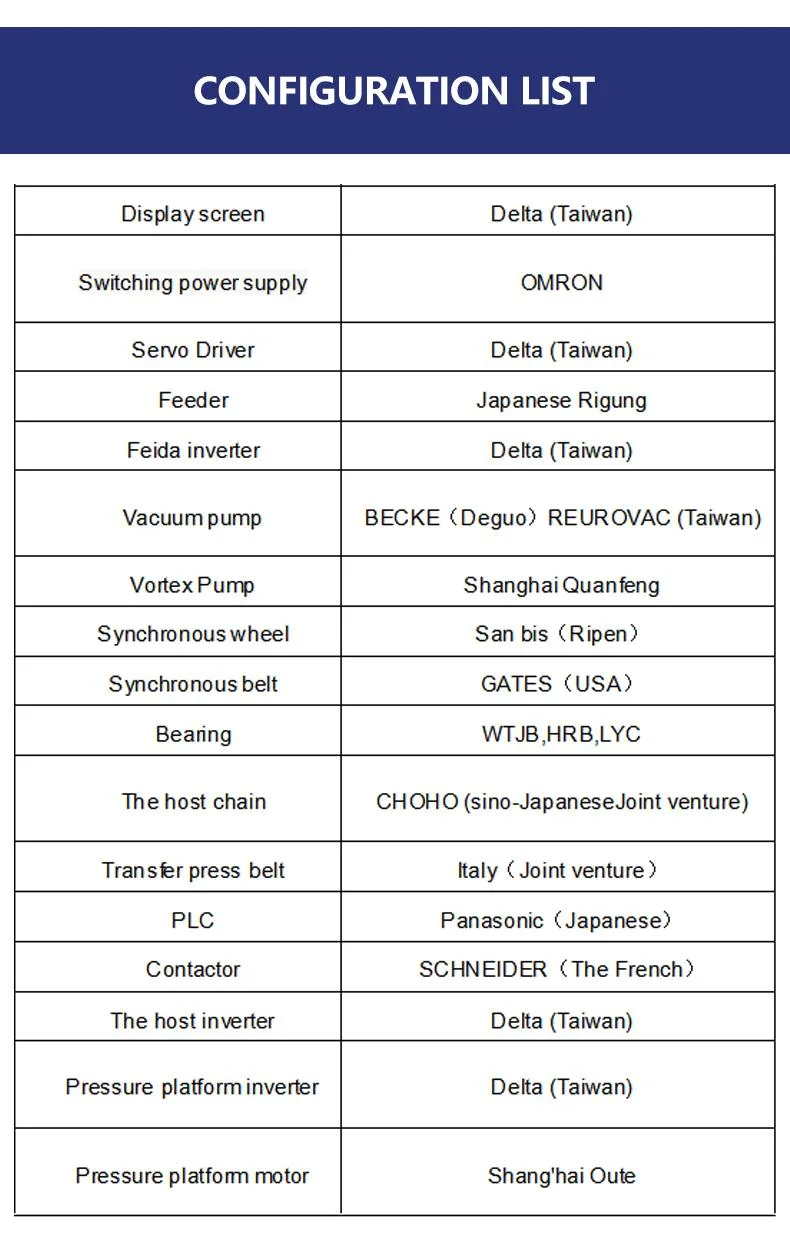

1.Suitable for laminating of cardboard and corrugated cardboard in 150-600 g/m2 .2.The vacuum suction-type feeding system can lead the paper accurately into themachine;cycle stacking planes in a state of non-stop the next batch of paper stack well, so that more efficient.3.Using suction automatic feeding of bottom sheet, accoding to the main machine operating speed, continuous automatic tracking.4.The machine operation is stable, surface paper with corrugated paper joint very accurate. The corrugated paper never pull ahead, surface paper's location is easy adjust.5.Machine uses touch-screen/PLC/servo motor control system, double frequency control type , the circuit system is stable, and can automatically display the failure alarm.6.Automatic gluing, and the glue can be used circulatory, avoid glue waste.7.Measure roller line-speed design scientifically, avoid glue fly out when the speed is high.8.Pressure rollers adopt unilateral adjustment, convenient and fast.9.Cleaning type : bottom roller is extruded by rubber roller to clean the bottom laminating pressure roller, ensure the cleaner on the reverse of the bottom paper . Make glue etc. foreign matter after washing direct subside in tank. At the same time , adopting the gear and chain to control the lifting of tank, can take out the tank easily and convenient to wash .10.The pressure conveyor adopt floating movable structure , total length 5m , equipped with 28 paper pressing rollers , make the cardboard uniform bearing strength in pressing process.11.Counter designs scientifically, easy recording the amount you have been worked.12.Small pressure table (optional) . length 2.5m , big pressure table length 5m. Product Details

Rino is a fast growing group company mainly committed to manufacturing and exporting high quality products with reasonable price to fulfill the needs of the most rigorous buyers. With the development of 20 years ,Rino Group already established flexo printing machine plant ,manual die cutting machine plant ,corrugated production line plant in Hebei province , Our company has nearly 20 years of experience in carton packaging production and professional technical team which can provide reasonable packaging solutions, after-sales service, timely and comprehensive for each customer.

FAQ

1

Q:What is the machine warranty?

A:one year.

2

Q:Does your machine with CE certificate?

A:Yes, issued by Italian organization

3

Q:What is the production time while placing order?

A:About 30 days

4

Q:What is the delivery time?

A:45-60days after get the payment

5

Q:Can your company handle shipping for customers?

A:Yes, just give us destination sea port or container yard

6

Q:Does the packing strong?

A:Yes, all packages are double-checking before delivery

7

Q:How about after-sales service process?

A: We offer life time A.S.S. Please feel free to contact after-sales department.

8

Q:Do you have machines in stock?

A: for standard model, we have a large quantity in stock. For special model, we need 20-30 days to produce it for you.

9

Q:Do you inspect machines before packing?

A:Of course we do.we have QC department to debug the machine before packing

10

Q:What's the payment term?

A:T/T 30% in advance, the balance paid before delivery.

11.

Q: Do you accept factory visiting?

A:We are highly greeting for your visiting.