Automatic Laminator Paper Laminating Machine Paperboard Laminating Machine Roll Laminating Machine Laminating Machine

Basic Info

| Model NO. | gojon-004 |

| After-sales Service | Engineer on Site |

| Warranty | 12 Months |

| Usage | Packaging of Goods, Produce Packing Belt, Corrugated Cardboard and Carton Box |

| Packaging Material | Bamboo, Wood |

| Packaging | Cartons |

| Driven Type | Electric |

| Type | Packaging Production Line |

| Function | Transport Packaging, Storage and Packaging, Sales Packing, Corrugated Cardboard and Carton Box |

| Packaging Technology | Shockproof Packaging |

| Application | Drinks, Dairy Products, Cleaning, Detergent, Oil, Tea, Vegetable, Fruit, Fish, Meat, Snack, Rice, Flour, Hair Care Products, Carton Box |

| Soft and Hardness | Flexible Package |

| Circulation Function | Outer Packing |

| Frequency of Use | Several Packaging |

| Mode of Operation | Packaging of Export Products |

| Transport Package | Container |

| Specification | Customzied |

| Trademark | GOJON |

| Origin | Qingdao |

| HS Code | 84418090 |

Product Description

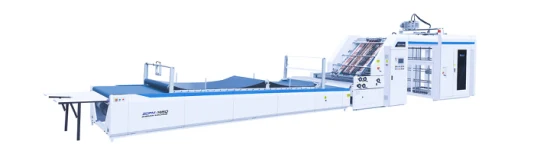

1.SAL SERIES SERVO MOTOR HIGH SPEED AUTOMATIC LAMINATOR

SAL Series servo high speed automatic laminator is a new generation laminator developed by our company. The top sheet deviation can be corrected accurate by the double servo system , the max. speed is 12000P/H, is an ideal solution for users with demand of high speed, high efficiency and high precision.

2.FEATURE:

Top sheet feeding section:

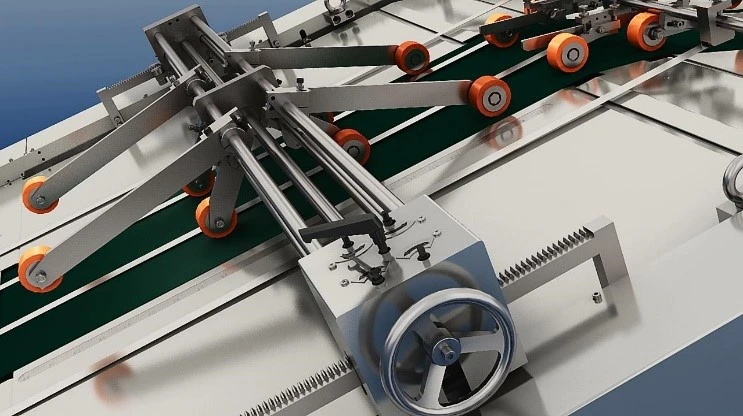

- The stacking table for back up can be used for the preparation of next batch without stopping the machine, pushing it into the machine along with the track, precise location, and high working efficiency.

- Using dual oriented open type pre-stack side register, the side register could positioning accurately and without repeating adjustment when change stack;

- High speed feeder can ensure the stable feeding when the equipment running in 12000 / hour speed.

- In order to realize non-stop stack changing function, nonstop feed mechanism can be optional

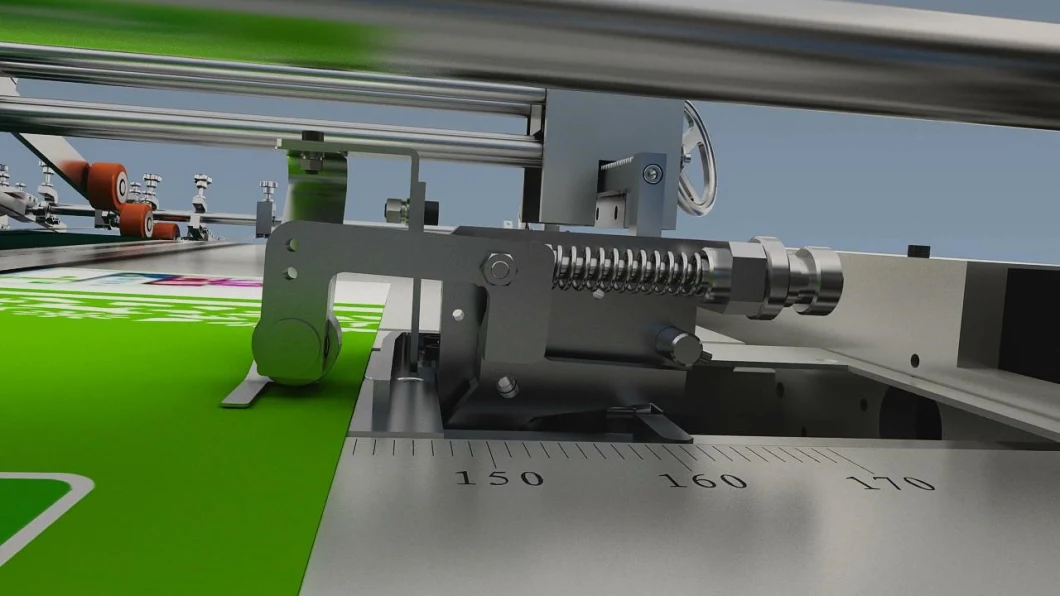

Top sheet transfer sectionThe pressure of the roller type side pulling register can be adjusted, which could highly improve the accuracy of the side register for top sheet, easy to adjust the structure of the organ bridge. Side layThe position and pressure of the press wheel can be adjusted quickly on the operation position.Bottom sheet feeding and glue unit section

- Using the technology of lifting type advancing edge paper feed mechanism to improve the accuracy of feeding and extend belt life.

- Using multi-function supporting rack(patent technology), the height of support roller can be adjusted according to the need which can adapt to the warping corrugated cardboard; according to the difference of the warping degree, choose different height and different numbers of the support roller.

- Using synchronous air valve (patent technology) to keep the suction pressure stable, effectively improve the feed precision.

- The uses of the whole process of vacuum adsorption belt feeding (patented technology) can smooth and reliable delivery of paper, effectively reduce the damage to the board, as well as greatly improve the compressive strength of the carton.

- Return glue device, to ensure the stability of the glue liquid properties, improve the utilization rate of glue

- Water clean section could effective control of board warping;

- In order to easy deal with warping board, the feeding pressure device could be optional.

- Using the top sheet and bottom sheet synchronous feeding patent technology to make sure two papers have a same rhythm.

- Through the servo correction system in real time to adjust the back and forth deviation and tilt deviation, then to guarantee the high efficiency and high precision.

- The position of the upper press belt can be adjusted according to the size of the cardboard

- The upper pressure transmission belt pressure adjustment device can be optional to meet the different requirements of cardboard.

Automatic control system

- The whole machine is equipped with internationally renowned brands, high reliability;

- The man-machine interface can reflect the working status of the machine; the top sheet advanced quantity can be adjusted according to the requirement which is convenient and quickly;

- Single sheet feeding function which can realize the single laminate test.

- The video monitoring system in the main operation side can be optional which could have a real-time monitoring of the key position of the running state;

3.SPECIFICATION:

| 1 | Model | SAL1450 |

| 2 | Max. Laminating size (mm) | 1450x1450mm |

| 3 | Min. Laminating size (mm) | 400x400mm |

| 4 | Weight of top sheet (g/m2) | 180~450g/m2 |

| 5 | Suitable bottom sheet | 1~12mm |

| 6 | Laminating Accuracy | ±1 mm |

| 7 | Top speed | 12000P/H |

| 8 | Total power rate (kw) | Siemen28kW |

| 9 | Total weight (kg) | 10700kg |

AUTO CONTROL:

Most of the electrical parts (PLC, VFD, Servo system, low-voltage apparatus) from international well-known brands, stable and reliable.

The top sheet deviation can be corrected by the double- servo system,providing high precision, and the over- forward dimension can be automatically controlled.

Automatic accelerating function, the setting speed can be achieved via this function after starting the machine

The Max. speed list for different sheet size:

| size | Max. speed SAL-1450 |

| Less than 550mm | 12000 |

| 650mm | 10000 |

| 750mm | 9000 |

| 850mm | 7000 |

| 950mm | 6200 |

| 1050mm | 5500 |

| 1150mm | 5100 |

| 1250mm | 4600 |

| 1350mm | 4300 |

| 1450mm | 4000 |

4.FAQ

| 1 | Do you have a minimum order quantity? | Yes, we require all international orders to have an ongoing minimum order quantity. But if you are looking to resell but in much smaller quantities, you can also contact us for further information |

| 2 | Can you supply the relevant documentation? | Yes, we can provide most documentation including Certificates of Analysis / Conformance; Insurance; Origin, and other export documents where required. |

| 3 | What kinds of payment methods do you accept? | You can make the payment to our bank account, Western Union or PayPal:30% deposit in advance, 70% balance against the copy of B/L. |

| 4 | What is the product warranty? | We warranty our materials and workmanship. Our commitment is to your satisfaction with our products. In warranty or not, it is the culture of our company to address and resolve all customer issues to everyone's satisfaction |

| 5 | How about the shipping fees? | The shipping cost depends on the way you choose to get the goods. Express is normally the most quickest but also most expensive way. By seafreight is the best solution for big amounts. Exactly freight rates we can only give you if we know the details of amount, weight and way. Please contact us for further information. |

5.Facilities & Capabilities